1. What is Overhead Cable ?

Overhead cable (full name overhead insulated cable) is an overhead wire equipped with an insulation layer and a protective sheath. It is a special cable manufactured by a production process similar to cross-linked cables. It is a new power transmission way between overhead wires and underground cables.Overhead Cable Advantages

1. It can simplify the structure of line poles and towers, and can even be laid along the wall, which not only saves line materials but also beautifies the city streets.

2. It is conducive to improving and enhancing the safety and reliability of the power distribution system, greatly reducing the risk of personal electric shock casualties, insulated wires can prevent phase-to-phase short circuits caused by foreign objects, reduce the number of power outages during the operation of the combined pole line, reduce maintenance workload, and improve Line power utilization.

3. Save the line power loss and reduce the voltage loss, the line reactance is only 1/3 of the ordinary bare wire line reactance.

4. Go deep into the load center at high voltage to improve voltage quality and reduce power loss.

5. Reduce the gravity requirements of the line, reduce the investment of fittings, and reduce the labor intensity of workers when setting up the wire.

6. It saves the space occupied by overhead lines and facilitates the passage of overhead lines in narrow passages. The line corridor is reduced, compared with the overhead bare wire, the line corridor can be reduced by 1/2.

7. Reduce wire corrosion, thereby improving the service life of the line and the reliability of power distribution.

8. Reduce the insulation requirements for line supports and increase the number of lines on the same pole. Due to the improvement of the technical status of the line, the maintenance workload is reduced, the maintenance cycle is extended, and the time of power outage due to maintenance is reduced.

Overhead Cable Shortcoming

1. The allowable current carrying capacity of high-voltage insulated overhead wires is smaller than that of bare wires, because after the plastic layer is added, the heat dissipation of the wires is poor, and the shape of overhead insulated wires should be higher than usual.

2. The wire diameter of the high-voltage insulated overhead wire is larger, and with the addition of a plastic sheath, the wire diameter is one grade larger than that of the steel-cored aluminum stranded wire with the same cross-section. Although insulated wires have many advantages, the unit cost is higher than that of bare wires, about twice as high for medium-voltage lines, and about 25% higher for low-voltage lines.

Environmental Requirements

1. When laying cables, the ambient temperature should not be lower than -20°C. When laying below -20°C, the cables must be heated in advance.2. When laying overhead cables, the bending radius of rated voltage 1kV overhead insulated cables should not be less than 6 times the outer diameter of the cable, and 101kV and 35KV overhead insulated cables should not be less than 15 times the outer diameter.

3. The erection method of the cable is the same as that of the bare overhead line. It still needs to be fixed on the insulator of the cross arm, but the distance can be appropriately reduced.

4. The cable should be used in conjunction with specially designed metal appliances for overhead insulated cables.

5. During laying construction and storage, attention should be paid to the sealing of the cable end to prevent the cable from entering the water and reducing its performance.

6. The long-term operating temperature of overhead cables (that is, the long-term allowable operating temperature of the cable conductive core), XLPE insulation should not exceed 90 ° C, high-density polyethylene insulation should not exceed 75 ° C; polyethylene, polyvinyl chloride insulation should not exceed 70°C; cross-linked polyethylene insulation should not exceed 250°C during short circuit; high-density polyethylene, polyvinyl chloride insulation should not exceed 150°C, and the longest duration should not exceed 5 seconds.

Overhead insulated cable products are a new series of products for overhead transmission lines to transmit electric energy and are preferred for power grid construction and transformation of 10kV transmission lines. It is the most suitable series of products for line maintenance and safety. Annealed copper core products are suitable for transformer lower leads.

2. The Difference Between Overhead Cables and Underground Cables

1. Different Useage

Overhead cables mainly refer to overhead open wires, erected above the ground, and are transmission lines that use insulators to fix the transmission wires on the towers standing on the ground to transmit electric energy.

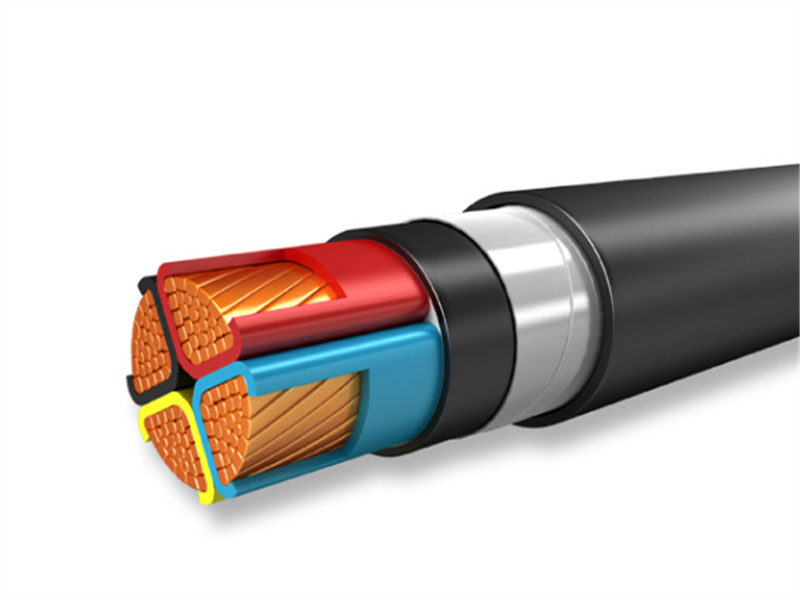

Underground cables refer to cables that are often buried underground compared with common overhead lines, so they are also called buried cables.

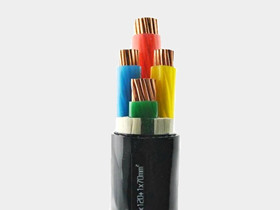

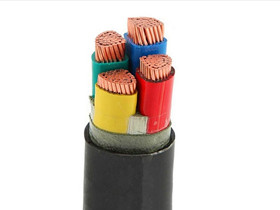

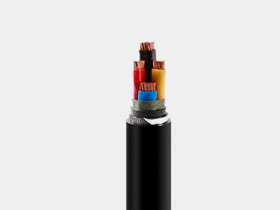

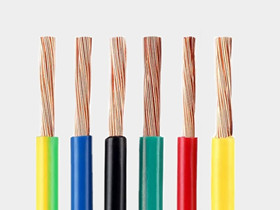

2. Different Materials

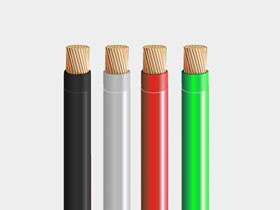

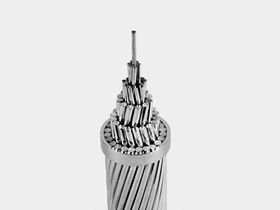

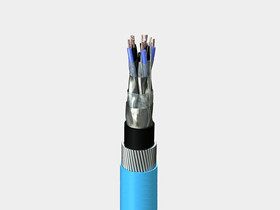

Aerial cables generally use steel-cored aluminum strands as conductors. Steel has high strength and is not easy to break. Aluminum has a low specific gravity and is easy to install. It can also be used for overhead interception. If the distance is not long, the steel core can also be used. Use aluminum wire directly. If there is insulation, it is generally weather-resistant black polyethylene or cross-linked polyethylene, generally without a sheath.