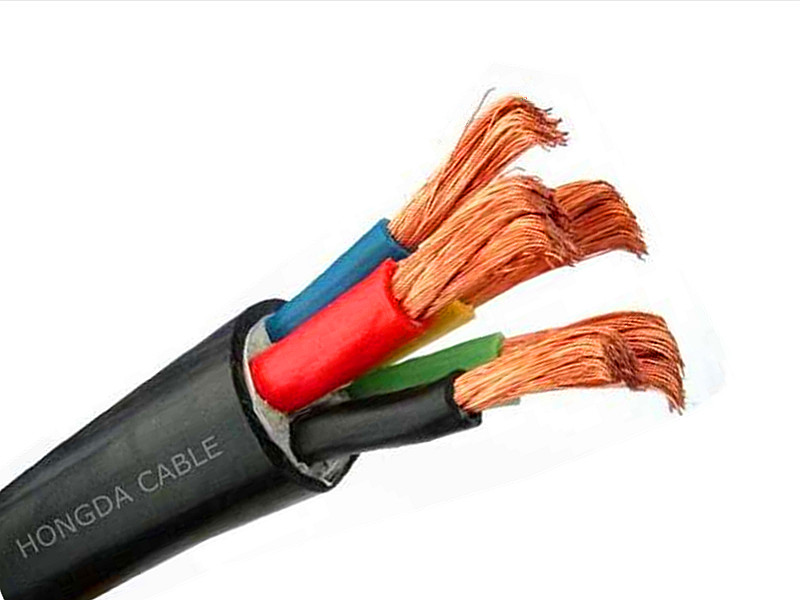

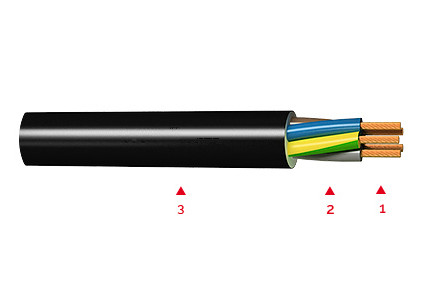

Industrial Cable with Flexible Copper Conductor XLPE Insulation and PVC Sheath

Conductor: Plain annealed copper, flexible

Insulation: XLPE

Sheath: Polyvinylchloride compound PVC 5V-90

Voltage : 0.6/1kV

Number of cores: Multi Core

Package Export wooden drum & iron wooden drum or as customer require

Email: manager@hdcable.com.cn

These cables are indicated for the transport and distribution of low voltage electricity. Recommended for industrial connections, service connections, internal distribution and other permanent installations. Suitable for indoor and outdoor installations, on uncovered cable trays, in tubes and buried.

Given their great flexibility they are very appropriate for complex and extremely difficult installations.

Maximum temperature :90 ºC

Nominal voltage:0,6/1 kV

Test voltage:3.500 V A.C.

Other characteristics:

UV Resistance: climatic test according to UNE 211605

Colours according to UNE 21089 and HD 308.S2 (colour marking when less than five conductors) and UNE-EN 50334 and EN 50334 (inscription marking when more than five conductors)

Non-flame propagating according to UNE-EN 60332-1-2, EN 60332-1-2 and IEC 60332-1-2

The use of cross-linked polyethylene (XLPE) admits greater current ratings comparing to the same size conductors in PVC

| Section (mm2) |

Resistance at 20 °C (Ohm/km) |

External Diameter (mm) |

Weight (kg/km) |

Class |

|---|---|---|---|---|

|

1x1,5 |

13,3 |

5,65 |

35 |

Eca |

|

1x2,5 |

7,98 |

6,05 |

45 |

Eca |

|

1x4 |

4,95 |

5,90 |

61 |

Eca |

|

1x6 |

3,3 |

6,55 |

82 |

Eca |

|

1x10 |

1,91 |

7,30 |

120 |

Eca |

|

1x16 |

1,21 |

8,50 |

178 |

Eca |

|

1x25 |

0,78 |

10,25 |

255 |

Eca |

|

1x35 |

0,554 |

11,55 |

351 |

Eca |

|

1x50 |

0,386 |

13,10 |

487 |

Eca |

|

1x70 |

0,272 |

15,05 |

674 |

Eca |

|

1x95 |

0,206 |

17,60 |

901 |

Eca |

|

1x120 |

0,161 |

19,40 |

1.127 |

Eca |

|

1x150 |

0,129 |

21,80 |

1.410 |

Eca |

|

1x185 |

0,106 |

23,60 |

1.728 |

Eca |

|

1x240 |

0,0801 |

26,80 |

2.239 |

Eca |

|

1x300 |

0,0641 |

29,90 |

2.790 |

Eca |

|

1x400 |

0,0486 |

33,20 |

3.632 |

Eca |

|

1x500 |

0,0384 |

40,00 |

4.882 |

Eca |

|

1x630 |

0,0287 |

48,00 |

6.504 |

Eca |

|

2x1,5 |

13,3 |

8,25 |

92 |

Eca |

|

2x2,5 |

7,98 |

9,10 |

120 |

Eca |

|

2x4 |

4,95 |

10,05 |

158 |

Eca |

|

2x6 |

3,3 |

11,20 |

209 |

Eca |

|

2x10 |

1,91 |

12,80 |

306 |

Eca |

|

2x16 |

1,21 |

16,50 |

532 |

Eca |

|

2x25 |

0,78 |

20,80 |

786 |

Eca |

|

2x35 |

0,554 |

22,60 |

1.014 |

Eca |

|

2x50 |

0,386 |

25,70 |

1.409 |

Eca |

|

3G1,5 |

13,3 |

8,85 |

109 |

Eca |

|

3G2,5 |

7,98 |

9,70 |

145 |

Eca |

|

3G4 |

4,95 |

10,90 |

198 |

Eca |

|

3G6 |

3,3 |

11,95 |

260 |

Eca |

|

3G10 |

1,91 |

13,70 |

390 |

Eca |

|

3x16 |

1,21 |

17,55 |

663 |

Eca |

|

3x25 |

0,78 |

22,05 |

978 |

Eca |

|

3x35 |

0,554 |

24,30 |

1.296 |

Eca |

|

3x50 |

0,386 |

27,60 |

1.799 |

Eca |

|

3x70 |

0,272 |

31,80 |

2.400 |

Eca |

|

3x95 |

0,206 |

35,90 |

3.178 |

Eca |

|

3x120 |

0,161 |

41,80 |

4.067 |

Eca |

|

4G1,5 |

13,3 |

9,60 |

132 |

Eca |

|

4G2,5 |

7,98 |

10,60 |

175 |

Eca |

|

4G4 |

4,95 |

11,80 |

239 |

Eca |

|

4G6 |

3,3 |

13,20 |

323 |

Eca |

|

4G10 |

1,91 |

15,20 |

488 |

Eca |

|

4x16 |

1,21 |

19,10 |

813 |

Eca |

|

4x25 |

0,78 |

24,00 |

1.193 |

Eca |

|

4x35 |

0,5554 |

27,15 |

1.609 |

Eca |

|

4x50 |

0,386 |

30,75 |

2.244 |

Eca |

|

4x70 |

0,272 |

35,30 |

3.124 |

Eca |

|

4x95 |

0,206 |

42,50 |

4.303 |

Eca |

|

4x120 |

0,161 |

46,60 |

5.237 |

Eca |

|

5G1,5 |

13,3 |

10,40 |

152 |

Eca |

|

5G2,5 |

7,98 |

11,40 |

206 |

Eca |

|

5G4 |

4,95 |

12,90 |

284 |

Eca |

|

5G6 |

3,3 |

14,50 |

388 |

Eca |

|

5G10 |

1,91 |

16,80 |

597 |

Eca |

|

5G16 |

1,21 |

20,85 |

965 |

Eca |

|

5G25 |

0,78 |

26,60 |

1.478 |

Eca |

|

5G35 |

0,5554 |

29,60 |

1.936 |

Eca |

|

5G50 |

0,386 |

34,00 |

2.751 |

Eca |

|

5G70 |

0,272 |

40,00 |

3.852 |

Eca |

|

5G95 |

0,206 |

45,00 |

4.879 |

Eca |