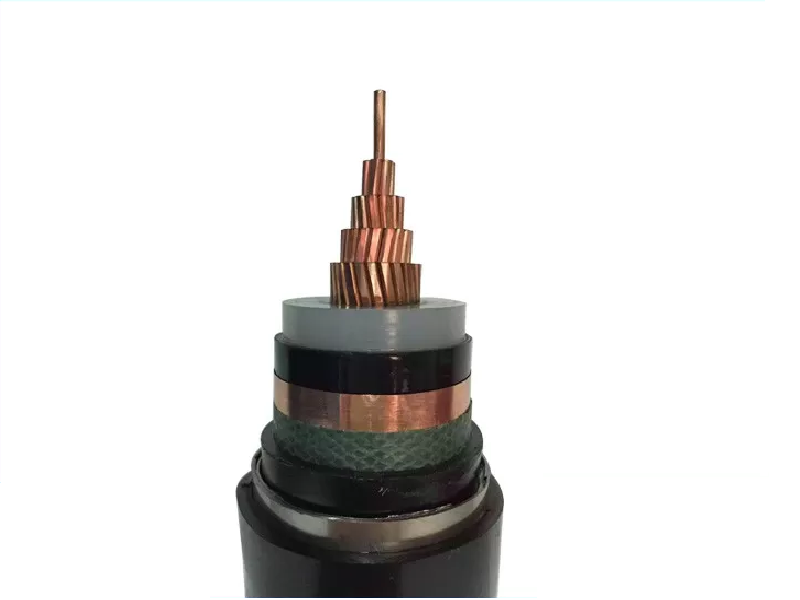

Single Core 8.7/15KV (Um=17.5KV) Armoured

Voltage: 8.7/15kV

Conductor: Copper or Aluminum

Operating Temperature: up to 90°C

Short Circuit Temperature: 250°C

Bending Radius: 12 x OD

Email: manager@hdcable.com.cn

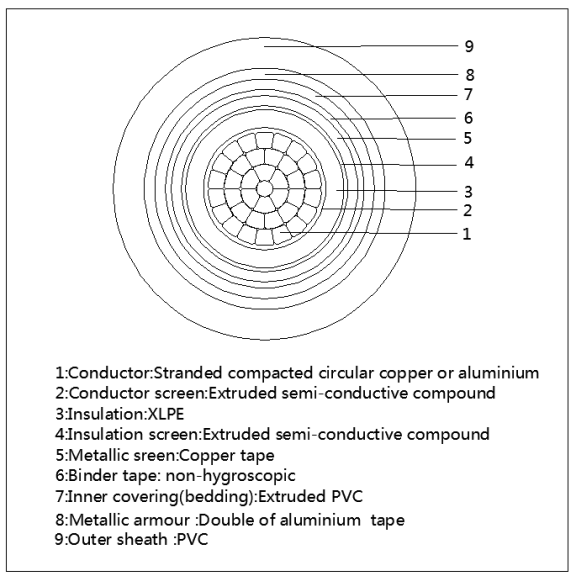

Conductor: Plain annealed stranded compacted circular copper or aluminium conductor to IEC60228 class 2

Conductor Screen: Extruded semi-conductive compound

Insulation: XLPE (cross-linked polyethylene) rated at 90°C

Insulation Screen: Extruded semi-conductive compound

Metallic Screen: copper tape or a concentric layer of copper wires

Color for core identification: Red, Yellow ,Blue tape shall be applied between insulation screen and metallic screen ( The above identifying can be changed as user requirement)

Assembly : Three screened cores are laid up together ,if necessary filled with non-hygroscopic material compatible with insulation and covered with a layer of PVC sheath

Inner Sheath: Extruded layer of PVC ST2 or PE , LSZH

Armour : Double of aluminium tape or aluminium wire for single power cable ,Double of galvanized steel tape or galvanized steel wire for three core power cable ,

Outer Sheath: PVC type ST2 to IEC 60502 or PE ,LSZH

|

Specification |

Outer diameter |

Nominal thickness of insulation |

Aluminium tape Layer×thickness |

Nominal sheath thickness |

Approx. Outer diameter of cable |

Approx. Weight of cable |

Ampacity of cable |

||||

|

Air |

Soil |

||||||||||

|

CU |

AL |

Cu |

Al |

Cu |

Al |

||||||

|

mm2 |

mm |

mm |

mm |

mm |

mm |

kg/km |

kg/km |

A |

A |

A |

A |

|

1×25 |

6.0 |

4.5 |

2×0.5 |

1.8 |

25.4 |

999.0 |

846.75 |

170 |

130 |

160 |

125 |

|

1×35 |

7.0 |

4.5 |

2×0.5 |

1.8 |

26.4 |

1129.7 |

917.5 |

205 |

160 |

195 |

150 |

|

1×50 |

8.4 |

4.5 |

2×0.5 |

1.8 |

27.8 |

1313.3 |

1016.7 |

245 |

190 |

230 |

175 |

|

1×70 |

10.0 |

4.5 |

2×0.5 |

1.9 |

29.5 |

1578.4 |

1157.0 |

310 |

240 |

280 |

215 |

|

1×95 |

11.5 |

4.5 |

2×0.5 |

1.9 |

31.2 |

1870.2 |

1292.7 |

380 |

295 |

335 |

260 |

|

1×120 |

13.0 |

4.5 |

2×0.5 |

2.0 |

32.7 |

2173.4 |

1443.0 |

435 |

340 |

385 |

295 |

|

1×150 |

14.5 |

4.5 |

2×0.5 |

2.0 |

34.3 |

2510.8 |

1593.1 |

495 |

385 |

430 |

335 |

|

1×185 |

16.2 |

4.5 |

2×0.5 |

2.1 |

37.4 |

2919.5 |

1783.4 |

570 |

440 |

485 |

380 |

|

1×240 |

18.4 |

4.5 |

2×0.5 |

2.2 |

39.8 |

3532.6 |

2053.1 |

680 |

530 |

565 |

440 |

|

1×300 |

20.5 |

4.5 |

2×0.5 |

2.3 |

42.1 |

4172.8 |

2315.6 |

780 |

605 |

640 |

500 |

|

1×400 |

23.5 |

4.5 |

2×0.5 |

2.4 |

45.5 |

5166.9 |

2744.7 |

910 |

715 |

735 |

575 |

|

1×500 |

26.5 |

4.5 |

2×0.5 |

2.5 |

48.8 |

6296.3 |

3218.5 |

1060 |

835 |

840 |

660 |

|

1×630 |

30.0 |

4.5 |

2×0.5 |

2.6 |

52.6 |

7631.1 |

3776.8 |

1230 |

930 |

950 |

755 |

|

Nominal section area (mm2) |

Copper conductor(Ω/km) |

Aluminum conductor(Ω/km) |

|

1.5 |

12.1 |

- |

|

2.5 |

7.41 |

12.1 |

|

4 |

4.61 |

7.41 |

|

6 |

3.08 |

4.61 |

|

10 |

1.83 |

3.08 |

|

16 |

1.15 |

1.91 |

|

25 |

0.727 |

1.20 |

|

35 |

0.524 |

0.868 |

|

50 |

0.387 |

0.641 |

|

70 |

0.268 |

0.443 |

|

95 |

0.193 |

0.320 |

|

120 |

0.153 |

0.253 |

|

150 |

0.124 |

0.206 |

|

185 |

0.0991 |

0.164 |

|

240 |

0.0754 |

0.125 |

|

300 |

0.0601 |

0.100 |

|

400 |

0.0470 |

0.0778 |

|

500 |

0.0366 |

0.0605 |

|

630 |

0.0283 |

0.0469 |

Max. Permissible short-circuit current for conductor (reference value)

|

Nominal section area (mm2) |

Maximum permissible short-circuit current for conductor(1s)(KA) |

|

|

Copper conductor |

Aluminum conductor |

|

|

1.5 |

0.12 |

0.13 |

|

2.5 |

0.32 |

0.22 |

|

4 |

0.50 |

0.34 |

|

6 |

0.76 |

0.51 |

|

10 |

1.51 |

0.99 |

|

16 |

2.39 |

1.56 |

|

25 |

3.69 |

2.42 |

|

35 |

5.15 |

3.37 |

|

50 |

7.31 |

4.79 |

|

70 |

10.2 |

6.68 |

|

95 |

13.8 |

9.03 |

|

120 |

17.4 |

11.4 |

|

150 |

21.7 |

14.2 |

|

185 |

26.7 |

17.5 |

|

240 |

34.6 |

22.6 |

|

300 |

43.1 |

28.2 |

|

400 |

57.4 |

37.65 |

|

500 |

71.7 |

47.0 |

|

630 |

88.8 |

58.0 |