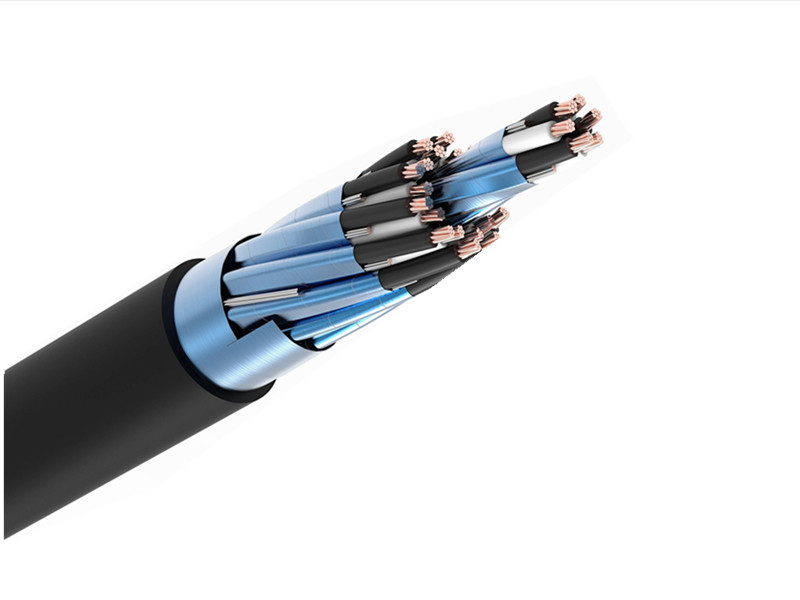

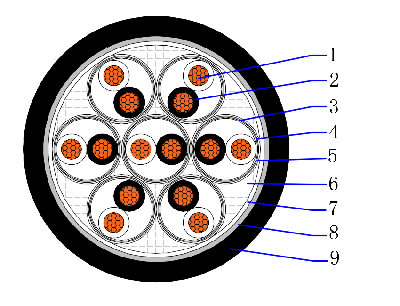

Individually & Collectively Screened Un-armoured Instrument Cables

Conductor: Annealed copper

Insulation : Crosslinked Polyethylene (XLPE)

Binder tape: Polyester tape

Screen: Al-PET tape with tinned copper drain wire

Outer sheath: Polyvinyl chloride compound (PVC)

Package : Export wooden drum & iron wooden drum or as customer require

Email: manager@hdcable.com.cn

Conductor operating temperature: -20℃~90℃

Min. installation temperature: 0℃

| Conductor Area Size | mm 2 | 0.5 | 0.75 | 1.5 | |

| Conductor Stranding | No. x mm | 16 x 0.2 | 24 x 0.2 | 7 x 0.53 | |

| Conductor resistance max | ohm/km | 39.7 | 26.5 | 12.3 | |

| Insulation resistance min | Mohm/km | 25 | 25 | 25 | |

| Max. Mutual Capacitance:pair or adjacent cores | pF/m | 250 | 250 | 250 | |

| Capacitance between any core or screen max. | pF/m | 400 | 400 | 400 | |

| Max. L/R Ratio for adjacentcores(Inductance/Resistance) | μH/ohm | 25 | 25 | 40 | |

| Test voltage | Core to core | V | 1000 | 1000 | 1000 |

| Core to screen | V | 1000 | 1000 | 1000 | |

| Rated voltage max | V | 300/500 | 300/500 | 300/500 | |

|

No.of Cores |

No.and Dia. of Wires |

Nominal Conductor Cross-Sectional Area |

Nominal Thickness of Insulation |

Nominal Thickness of Sheath |

Nominal Dia. of Cable |

Approx. Weight |

|

no./mm |

mm^2 |

mm |

mm |

mm |

kg/km |

|

|

2 |

16/0.2 |

0.5 |

0.6 |

1.1 |

11.2 |

170 |

|

5 |

16/0.2 |

0.5 |

0.6 |

1.2 |

14.6 |

270 |

|

10 |

16/0.2 |

0.5 |

0.6 |

1.3 |

19.4 |

520 |

|

15 |

16/0.2 |

0.5 |

0.6 |

15 |

22.7 |

650 |

|

20 |

16/0.2 |

0.5 |

0.6 |

1.5 |

25.9 |

860 |

|

30 |

16/0.2 |

0.5 |

0.6 |

1.7 |

31.2 |

1130 |

|

50 |

16/0.2 |

0.5 |

0.6 |

2.2 |

40.1 |

1880 |

|

2 |

24/0.2 |

0.75 |

0.6 |

1.1 |

12.2 |

200 |

|

5 |

24/0.2 |

0.75 |

0.6 |

1.2 |

15.8 |

355 |

|

10 |

24/0.2 |

0.75 |

0.6 |

1.3 |

21.1 |

560 |

|

15 |

24/0.2 |

0.75 |

0.6 |

1.5 |

24.9 |

770 |

|

20 |

24/0.2 |

0.75 |

0.6 |

1.7 |

28.6 |

990 |

|

30 |

24/0.2 |

0.75 |

0.6 |

2 |

34.7 |

1380 |

|

50 |

24/0.2 |

0.75 |

0.6 |

2.2 |

43.9 |

2225 |

|

2 |

7/0.53 |

1.5 |

0.6 |

1.2 |

13.6 |

265 |

|

5 |

7/0.53 |

1.5 |

0.6 |

1.3 |

147.8 |

490 |

|

10 |

7/0.53 |

1.5 |

0.6 |

1.5 |

24.1 |

820 |

|

15 |

7/0.53 |

1.5 |

0.6 |

1.7 |

28.2 |

1110 |

|

20 |

7/0.53 |

1.5 |

0.6 |

1.7 |

31.9 |

1470 |

|

30 |

7/0.53 |

1.5 |

0.6 |

2 |

38.8 |

2070 |

|

50 |

7/0.53 |

1.5 |

0.6 |

2.2 |

49.1 |

3340 |