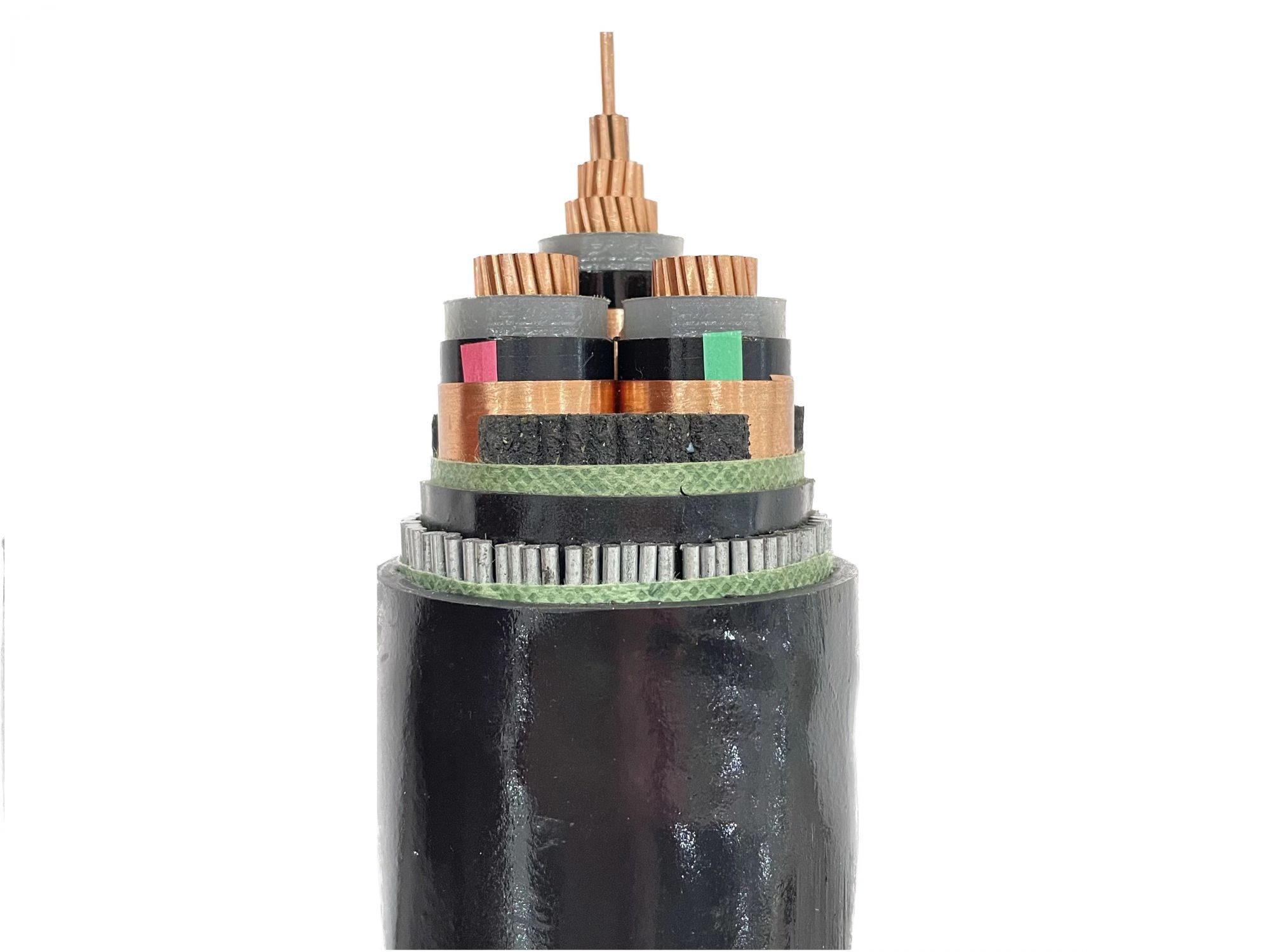

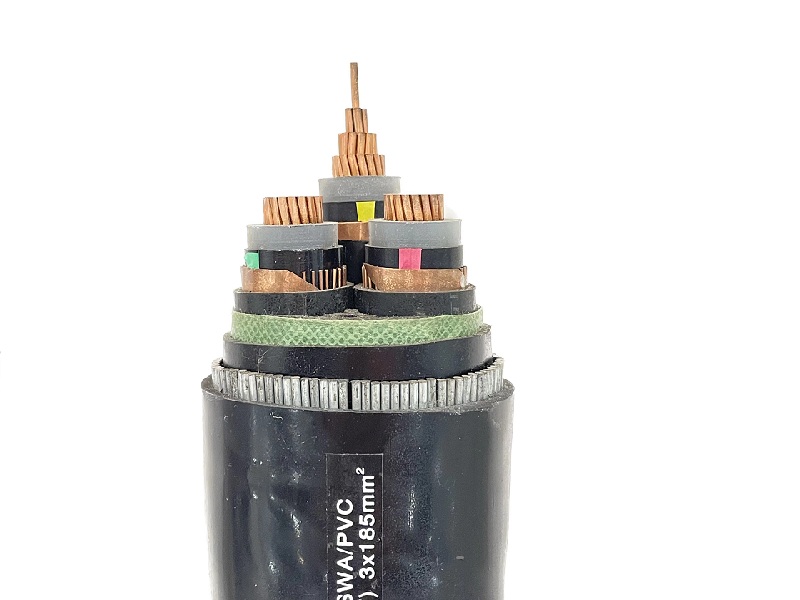

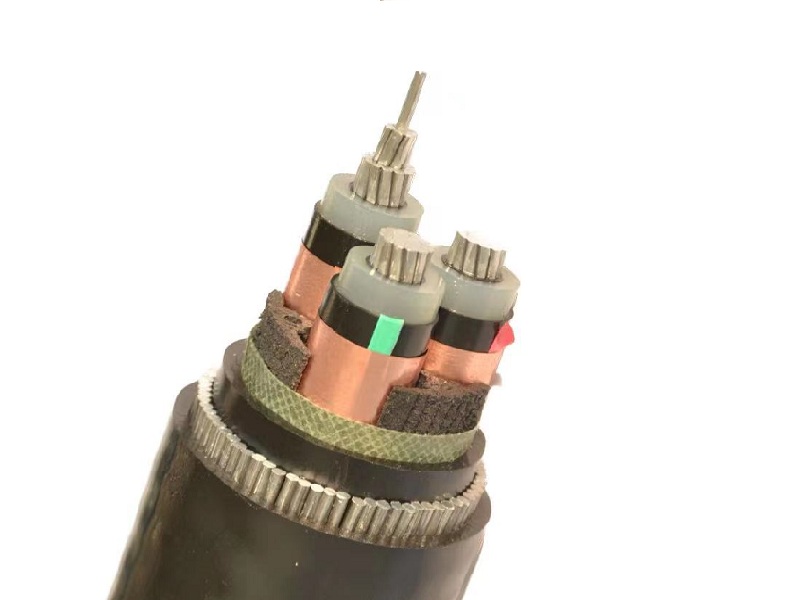

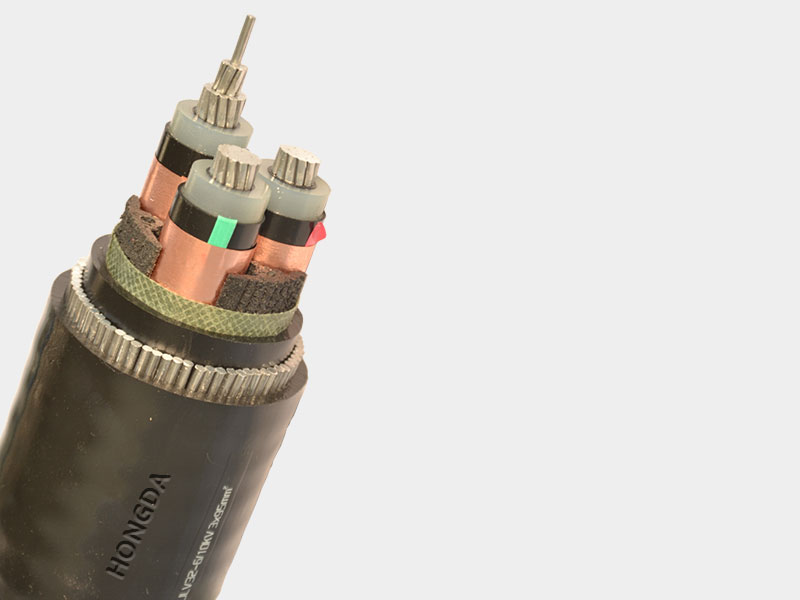

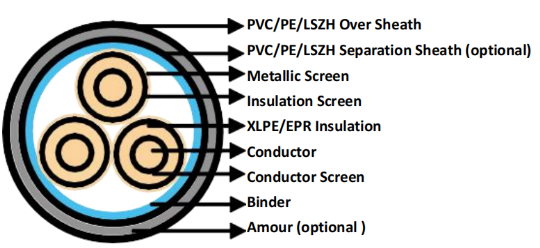

Three Core 19/33KV (Um=36KV) Armoured

Voltage: 18/30KV

Conductor: Copper or Aluminum

Operating Temperature: up to 90°C

Short Circuit Temperature: 250°C

Bending Radius: 15 x OD

Email: manager@hdcable.com.cn

Table 1. Insulation Thickness

|

Nom. Cross Section Area |

Insulation Thickness at Nom. Voltage |

||||

|

3.8/6.6KV(Um=7.2KV) |

6.35/11KV(Um=12KV) |

8.7/15KV(Um=17.5KV) |

12.7/22KV(Um=24KV) |

19/33KV(Um=36KV) |

|

|

mm² |

mm |

mm |

mm |

mm |

mm |

|

70 – 185 |

2.5 |

3.4 |

4.5 |

5.5 |

8.0 |

|

240 |

2.6 |

3.4 |

4.5 |

5.5 |

8.0 |

|

300 |

2.8 |

3.4 |

4.5 |

5.5 |

8.0 |

|

400 |

3.0 |

3.4 |

4.5 |

5.5 |

8.0 |

|

Above 500 |

3.2 |

3.4 |

4.5 |

5.5 |

8.0 |

Inner Covering & Fillers: For cables with a collective metallic layer or cables with a metallic layer over each individual cores with additional collective metallic layers, semi-conducting inner covering and fillers shall be applied over the laid up cores. The inner covering is made of non hygroscopic material, except if the cable is to be made longitudinally watertight. The inner covering shall be extruded or lapped.

The approximate thickness of extruded inner coverings is given in Table 2:

Table 2. Approximate Thickness of Extruded Inner Coverings

|

Ficititous Diameter over Laid Up Cores |

Approx. Thickress of Extruded Inner Covering |

|

|

mm |

mm |

|

|

> |

< |

|

|

35 |

45 |

1.0 |

|

25 |

35 |

1.2 |

|

35 |

45 |

1.4 |

|

45 |

60 |

1.6 |

|

60 |

80 |

1.8 |

|

80 |

- |

2.0 |

*The approximate thickness of lapped inner coverings shall be 0.6mm.

Metallic Layer: The metallic layer shall be applied over each core or applied as a collective screen. The metallic screen shall consist of either copper tapes or a concentric layer of copper wires or a combination of tapes and wires. The metallic layer provides an earth fault current path, capable of withstanding fault current to earth of 1000A for one second at maximum temperature 160°C. Copper wires are applied over the conducting water blocking layer with a minimum diameter of 0.5mm. And over the copper wires, copper tape with minimum thickness of 0.1mm can be applied helically with overlap.

Total cross section of copper wire screen is shown in Table 3.

Table 3. Minimum Total Cross Section of Copper Wire Screen & DC Resistance of The Screen

|

Nominal Cross-Section Area of Cable |

Minimum Cross-Section of Copper Wire Screen Area |

DC Resistance of the Copper Wire Screen |

|

mm² |

mm² |

mm |

|

up to 120 |

16 |

1.06 |

|

150-300 |

25 |

0.72 |

|

400-630 |

35 |

0.51 |

Separation Sheath (for armoured cable): The separation sheath comprises a layer of extruded PVC, PE or LSZH. The nominal thickness is calculated by 0.02Du + 0.6mm where Du is the fictitious diameter under the sheath in mm. The nominal separation sheath thickness shall not be less than 1.2mm.

Armour (for armoured cable): The armour consists of galvanized steel wire applied over the inner covering with diameter specified as in Table 4.

Table 4. Armour Wire Diameter

|

Fictitiious Diameter under the Armour |

Armour Wire Diameter |

|

|

mm |

mm |

|

|

> |

< |

|

|

|

25 |

1.6 |

|

25 |

35 |

2.0 |

|

35 |

60 |

2.5 |

|

60 |

- |

3.15 |

Over Sheath: Overall sheath comprises a layer of extruded either PVC type 9 conforming to BS 7665-4.2 or MDPE type TS2 conforming to BS 7655-10.1; LSZH can be offered as an option. The over sheath is normally black in colour. When a DC voltage test is to be performed on the over sheath, a semi-conducting layer such as graphite coating shall be applied over the surface of the extruded over sheath. The nominal over sheath thickness is calculated by 0.035+D where D is the diameter immediately under the over sheath in mm. For cables with the over sheath not applied over the armour, the nominal over sheath thickness shall not be less than 1.4mm. And for cables with over sheath applied over the armour, the nominal over sheath thickness shall not be less than 1.8mm.

Operating Temperature: up to 90°C

Temperature Range: -5°C ( PVC or LSZH sheath ); -20°C ( PE sheath )

Short Circuit Temperature: 250°C (short circuit duration up to 5 seconds)

Bending Radius: 15 x OD

Table 5. Nominal /Operating /Test Voltages

|

Rated Voltage Uo/U |

Operating Voltage (Um) |

Testing Voltage (rms) |

|

3.8/6.6KV |

7.2KV |

15KV |

|

6.35/11KV |

12KV |

25.5KV |

|

8.7/15KV |

17.5KV |

35KV |

|

12.7/22KV |

24KV |

51KV |

|

19/33KV |

36KV |

76KV |

|

Nom. Cross- Section Area |

|

Unarmoured Cables |

Steel Wire Armoured Cables |

||||||||||

|

Nom. Insulation Thickness |

Copper Wire Screen Area |

Nom. Sheath Thickness |

Approx. Overall Diameter |

Approx. Weight |

Copper Tape Screen Area |

Nom. Bedding Thickness |

Nom. Armour Wire Diameter |

Nom. Sheath Thickness |

Approx. Overall Diameter |

Approx. Weight |

|||

|

CU |

AL |

CU |

AL |

||||||||||

|

mm² |

mm |

mm² |

mm |

mm |

kg/km |

mm² |

mm |

mm |

mm |

mm |

kg/km |

||

|

35 |

8.0 |

16 |

3.1 |

60 |

3750 |

2880 |

6.5 |

1.7 |

2.5 |

3.2 |

74.9 |

9460 |

8700 |

|

50 |

8.0 |

16 |

3.2 |

65 |

5240 |

4260 |

6.7 |

1.8 |

3.15 |

3.4 |

79.0 |

10620 |

9680 |

|

70 |

8.0 |

16 |

3.3 |

70 |

6120 |

4730 |

7.1 |

1.8 |

3.15 |

3.5 |

82.5 |

11840 |

10440 |

|

95 |

8.0 |

16 |

3.4 |

74 |

7140 |

5240 |

7.5 |

1.9 |

3.15 |

3.6 |

86.4 |

13200 |

11350 |

|

120 |

8.0 |

16 |

3.5 |

77 |

8080 |

5710 |

7.9 |

2.0 |

3.15 |

3.7 |

89.9 |

14520 |

12190 |

|

150 |

8.0 |

25 |

3.6 |

80 |

9120 |

6220 |

8.2 |

2.0 |

3.15 |

3.8 |

93.6 |

16070 |

13280 |

|

185 |

8.0 |

25 |

3.7 |

84 |

10440 |

6940 |

8.6 |

2.1 |

3.15 |

3.9 |

97.3 |

17710 |

14090 |

|

240 |

8.0 |

25 |

3.9 |

91 |

12620 |

8010 |

9.2 |

2.2 |

3.15 |

4.1 |

103.2 |

20370 |

15460 |

|

300 |

8.0 |

25 |

4.0 |

95 |

14690 |

8800 |

9.7 |

2.3 |

3.15 |

4.3 |

108.2 |

22980 |

17210 |

|

400 |

8.0 |

35 |

4.3 |

103 |

17720 |

10230 |

10.3 |

2.4 |

3.15 |

4.5 |

116.8 |

27480 |

19450 |

|

Nom. Cross- Section Area |

|

Unarmored Cables |

Aluminium Wire Armoured Cables |

|

Current Ratings |

||||||||||

|

D C Resistance CU / AL |

A C Resistance CU / AL |

Short Circuit Rating of Conductor CU / AL 1 sec |

Capaci- tance |

Charging Current |

Short Circuit Rating of Copper Wire Screen Per Core 1 sec |

Short Circuit Rating of Copper Tape Screen Per Core 1 sec |

Reac- tance |

Induc- tance |

Ground |

Duct |

Air |

||||

|

CU |

AL |

CU |

AL |

CU |

AL |

||||||||||

|

mm² |

µΩ/m |

µΩ/m |

kA |

pF/m |

mA/m |

kA |

kA |

µΩ/m |

nH/m |

A |

A |

A |

|||

|

35 |

524/868 |

668/1113 |

5.0/3.2 |

132 |

0.79 |

2.6 |

0.9 |

140 |

460 |

170 |

135 |

155 |

120 |

180 |

145 |

|

50 |

387/641 |

494/822 |

6.8/4.4 |

142 |

0.85 |

2.6 |

1.0 |

134 |

430 |

210 |

160 |

185 |

140 |

225 |

175 |

|

70 |

268/443 |

343/568 |

9.8/6.3 |

159 |

0.95 |

2.6 |

1.0 |

127 |

400 |

255 |

195 |

225 |

170 |

275 |

215 |

|

95 |

193/320 |

248/410 |

13.3/8.5 |

175 |

1.05 |

2.6 |

1.1 |

121 |

390 |

295 |

230 |

260 |

205 |

330 |

260 |

|

120 |

153/253 |

196/325 |

17.2/11.0 |

189 |

1.13 |

2.6 |

1.1 |

117 |

370 |

335 |

260 |

300 |

235 |

380 |

300 |

|

150 |

124/206 |

159/265 |

21.2/13.5 |

201 |

1.21 |

4.3 |

1.2 |

113 |

360 |

375 |

290 |

335 |

265 |

430 |

335 |

|

185 |

99.1/164 |

128/211 |

26.6/17.0 |

217 |

1.30 |

4.3 |

1.2 |

109 |

350 |

420 |

330 |

380 |

300 |

490 |

390 |

|

240 |

75.4/125 |

98/161 |

34.9/22.3 |

237 |

1.42 |

4.3 |

1.3 |

104 |

330 |

480 |

380 |

430 |

345 |

570 |

460 |

|

300 |

60.1/100 |

80/130 |

43.8/28.0 |

258 |

1.55 |

4.3 |

1.4 |

101 |

320 |

530 |

425 |

480 |

385 |

650 |

520 |

|

400 |

47.0/77.8 |

64/102 |

57.3/36.6 |

282 |

1.69 |

5.8 |

1.5 |

96 |

290 |

590 |

480 |

520 |

420 |

700 |

570 |